HAYSTIX brand spears are a premium line of spear products, their quality and design rank them among the top spears on the market today! They are manufactured with T71 steel. They are the popular choice for dealers, OEM and welding shops. They are rigorously tested to accurately determine performance.

-

All standard spears are rated on a 30” load center. Most competitors are rated from a distance of 15”-20” from the sleeve.

-

1 5/8” (Conus I) spears are rated for 3,000 lbs

-

1 ¾” (Conus II) spears are rated at 3,500 lbs

-

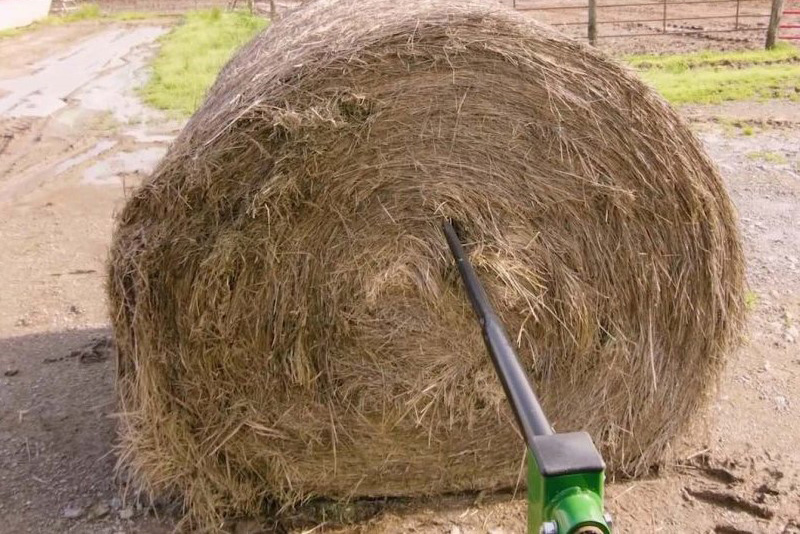

Based on a typical 5X6 round bale, tests for deflection and deformity indicate 100% return after load

-

Fatigue testing to 30,000 or more ensures durability and long life

-

HAYSTIX spears carry a limited 1 year warranty

The HAYSTIX DOUBLENUT spear, an exclusive of HAYSTIX, employs a jam nut with the conical nut on all their products. Incorporating the jam nut keeps the conical nut tight to the sleeve, eliminating flex inside the sleeve. This effectively reduces the most common spear failures and thread breakage issues.

The HAYSTIX spears are sold in 3 different configurations:

What kind and size of spear do you need to buy?

-

Pick the configuration you want to use from the above

-

If you are putting up 4X4’, 4X5’, or 4X6’ round hay bales, we recommend 43”-49” length.

-

If you are putting up 5X5’ or 5X6’ round hay bales, we recommend 48”- 55” length

-

The key to it is, for easy removal, you never want more than 85% of the spear thru the bale.

-

If you are putting up the large square hay bales, for the 3X3X8’ bale use the 33” long 3500 lb rated. On a 4X4X8’ use a spear that is 39”- 43” rated 3500 lbs.

-

For round cotton bales, use a 55”-84” rated to 3500 lbs. If you are building your own carrier, it is recommended to use a minimum of 4 spears but 5 is preferred to handle the load.

Some things to remember to maximize performance and move hay more safely:

-

When welding the sleeve into square tubing, NEVER weld the sleeve in while the spear is attached and NEVER weld a broken spear.

-

The conical nut on the tapered spear should be tightened to 200-300 ft lbs then install the jam nut. Routinely check the nut to make sure it remains tight. As a reminder, this is one of the major reasons for breakage at the threads.

-

NEVER, NEVER, NEVER use the spear for any purpose other than moving hay! Any application other than that is considered a product misuse and voids any warranty claims.

Need help with your HAYSTIX spears ?

When it comes to HAYSTIX spears, we’re trusted experts. Contact us or call 800-669-9650 to speak with a member of our customer service team at any of our 11 locations (Knoxville, TN; Marietta, GA; Orlando, FL; Charlotte, NC; Little Rock, AR; Fort Worth, TX; Benton, IL; Madisonville, KY; Princeton, WV; Birmingham, AL; Calvert City, KY).