In this blog:

- What are Thermoplastic Hoses?

- Key Advantages of Thermoplastic Hose Assemblies

- Use Case: Thermoplastic Hoses for Agriculture – Sprayers, Tractors, and Fluid Transfer

- Shop Thermoplastic Hoses

When it comes to fluid power and industrial systems, thermoplastic hoses offer a flexible, lightweight, and high-performance alternative to traditional rubber and metal hoses. Whether you're working in construction, agriculture, or manufacturing, thermoplastic hose assemblies can provide the durability and efficiency you need.

What are Thermoplastic Hoses?

Thermoplastic hoses are made from synthetic materials such as nylon, polyester, or polyurethane, typically reinforced with synthetic fiber or steel braids. Their multi-layered construction provides both flexibility and strength, making them suitable for high-pressure and high-temperature environments.

These hoses are commonly used in hydraulic, pneumatic, and chemical transfer applications and can be customized for specific needs like abrasion resistance, chemical compatibility, and compact installations.

Key Advantages of Thermoplastic Hose Assemblies

1. Lightweight and Flexible

One of the top advantages of thermoplastic hoses is their lightweight design. Compared to rubber or metal hoses, thermoplastic hoses are easier to handle, transport, and install. Their flexibility allows them to bend around tight corners or equipment without kinking or damage, which is particularly useful in mobile hydraulic applications.

2. High Pressure Ratings

Despite their light construction, thermoplastic hoses can handle high working pressures—often up to 6,000 PSI or more—depending on the hose type and construction. This makes them ideal for hydraulic systems, especially in compact or confined spaces where heavy-duty performance is still needed.

3. Abrasion and Chemical Resistance

Thermoplastic hose covers are designed to resist abrasion, chemicals, and UV exposure. This is critical for outdoor applications and those involving aggressive media like hydraulic fluid, grease, or solvents. The internal layers can also be engineered for chemical compatibility, protecting against corrosion and extending the hose life.

4. Non-Conductive Options for Electrical Safety

Many thermoplastic hydraulic hoses are available in non-conductive versions, making them safe for use near electrical equipment or in utility applications. These hoses are tested to meet strict standards for electrical resistance and are often color-coded for safety.

5. Low Permeability and Leak Prevention

The inner tube of a thermoplastic hose is designed to minimize permeability, which helps maintain system pressure and reduces the risk of leaks. This is especially important in applications like gas transfer, air conditioning, and refrigerant systems, where efficiency and environmental concerns are top priorities.

Use Case: Thermoplastic Hoses for Agriculture – Sprayers, Tractors, and Fluid Transfer

In the agriculture industry, efficiency and durability are critical, especially when it comes to managing fluids like fertilizers, herbicides, pesticides, and hydraulic oils. Thermoplastic hoses offer a high-performance solution for a wide range of farming equipment and processes. Here's how they play a key role across several ag applications:

1. Boom Sprayers & Spot Sprayers

Challenge: Boom arms and nozzles on agricultural sprayers need constant motion and flexibility. The hoses used must endure chemical exposure, UV rays, and repeated flexing without cracking, kinking, or leaking.

Thermoplastic Hose Solution:

- Lightweight and extremely flexible, allowing for smooth articulation across boom arms.

- High chemical resistance protects against degradation from fertilizers and herbicides.

- UV and weather-resistant outer cover ensures long-lasting performance in outdoor environments.

- Maintains pressure integrity for accurate and even spray patterns, reducing waste and increasing yield efficiency.

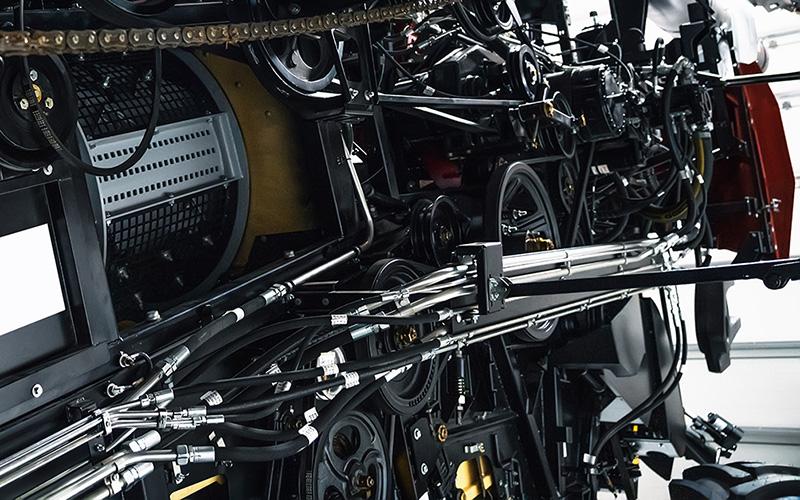

2. Tractor Hydraulic Systems

Challenge: Modern tractors rely heavily on hydraulic systems for attachments such as loaders, mowers, and tillers. These systems require hoses that can handle high pressure in tight spaces while standing up to dirt, vibration, and temperature extremes.

Thermoplastic Hose Solution:

- Compact, non-bulky design ideal for routing through tight engine bays and control panels.

- Excellent burst and pressure ratings support high-performance hydraulic attachments.

- Resistant to abrasion from dust, grit, and machinery movement.

- Non-conductive options available for electrical safety when operating near sensitive systems.

3. Chemical & Fluid Transfer for Fertilizer and Irrigation

Challenge: Farmers often transfer corrosive or chemically aggressive liquids like ammonium nitrate or liquid fertilizers through pumps and distribution lines. Hoses need to be safe, reliable, and leak-proof to avoid crop damage and environmental risk.

Thermoplastic Hose Solution:

- Internal liners can be customized for compatibility with corrosive agricultural chemicals.

- Low permeability ensures precise fluid delivery and prevents contamination or seepage.

- Flexible construction simplifies setup and storage, especially in portable pump systems.

- Reinforced designs available for suction and discharge lines, withstanding vacuum and backflow scenarios.

Bottom Line:

Thermoplastic hoses bring durability, chemical resistance, and flexibility to key farming operations. From boom sprayers and tractors to irrigation pumps and transfer tanks, they’re a smart, long-term investment for agricultural professionals who need reliable fluid delivery in tough outdoor conditions.

Royal Brass and Hose proudly supplies thermoplastic hose assemblies built for agriculture—available in custom lengths, with fittings and reinforcements that match your exact needs.

Shop Thermoplastic Hoses

- TH8 Theromplastic Hose SAE 100R8

- TH7 Thermoplastic Hose SAE 100R7

- TH7 Non-Conductive Thermoplastic Hose SAE 100R7

- 16TH8 Thermoplastic Hose SAE 100R8

Choosing the Right Thermoplastic Hose for Your Application

When selecting a thermoplastic hose, consider the working pressure, temperature range, hose size, chemical compatibility, and reinforcement type. Consult a trusted hose supplier to ensure your hose meets your system's exact requirements.

Thermoplastic hoses offer a combination of durability, flexibility, and resistance to environmental hazards that make them a reliable choice for many demanding applications. If you're looking to upgrade your fluid transfer system, consider switching to a thermoplastic hose assembly for long-term performance and efficiency.

Looking for the right hose solution? Contact our team to get help selecting the best thermoplastic hose for your application.