Does this sound familiar? You get in your car on a cold, winter Monday morning only to discover it won’t start because the battery died during the night. The kids are already loaded in their seats, your cup of coffee is piping hot, and you are on time for work. As you try fervently to crank your vehicle’s engine all you hear is the whirling sound of power loss to the system. Next thing you know, the kids are crying, your coffee is cold, and you are late for work as you wait to have someone come give you a boost.

We’ve all been there before and chances are we will all be there again one day. It’s easily one of the most frustrating ways to start a work-week. Disregarding the personal aspect of this situation, let’s think about it from a business standpoint. We all know that in business, time is money. Whenever a power loss like this happens to a work-truck, maintenance vehicle, tractor or construction implement it could lead to a loss of business and the loss of bottom-line dollars.

While it is inevitable that vehicle batteries will need to be charged or replaced over time, we recognize the importance of having the proper components needed to sustain and improve the life of your battery. Royal Brass and Hose is a prime dealer of QuickCable brand battery cables, connectors, tools, and accessories. We also specialize in assembling battery cables to custom lengths and specifications.

There are five major QuickCable product types we distribute and use for assemblies:

- Connectors - Clamps and Lugs

- Battery and Welding Cable

- Heat Shrinkable Tubing

- Assembly Protection Products

- Crimpers and Cutters

Through this tutorial we will examine the details of those five categories along with demonstrating how they are correctly assembled.

Copper Die Cast Connectors

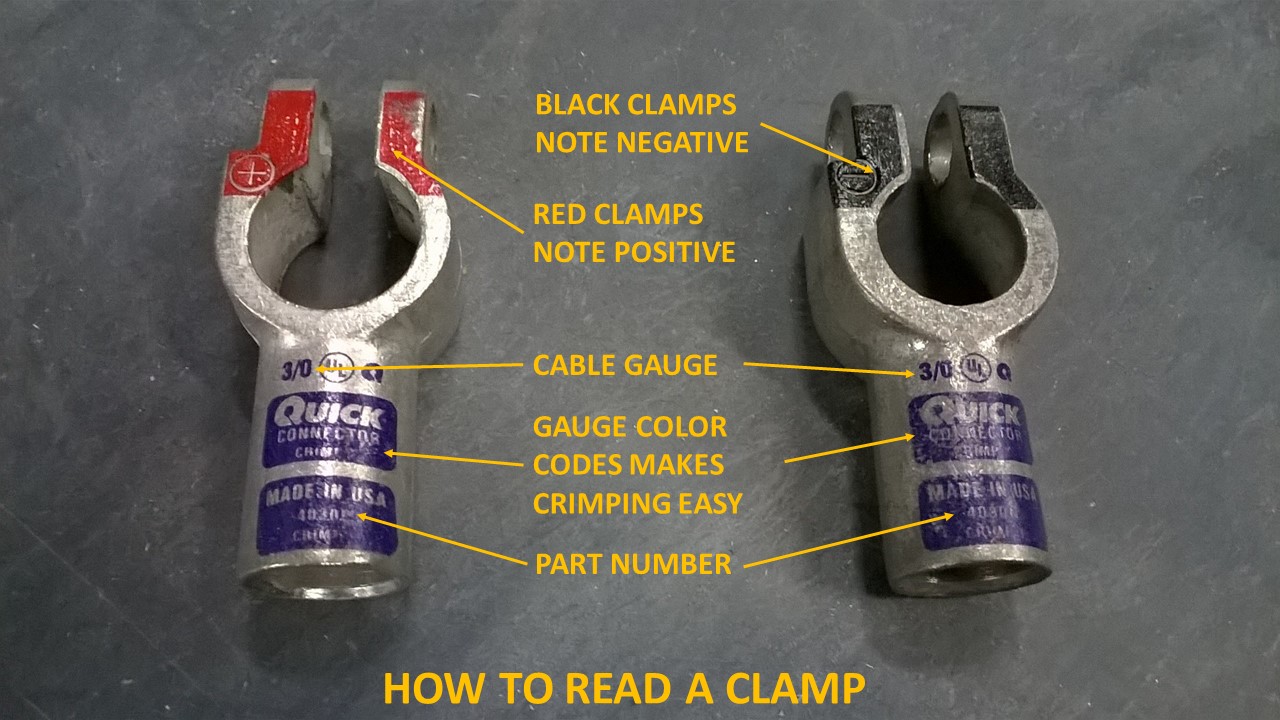

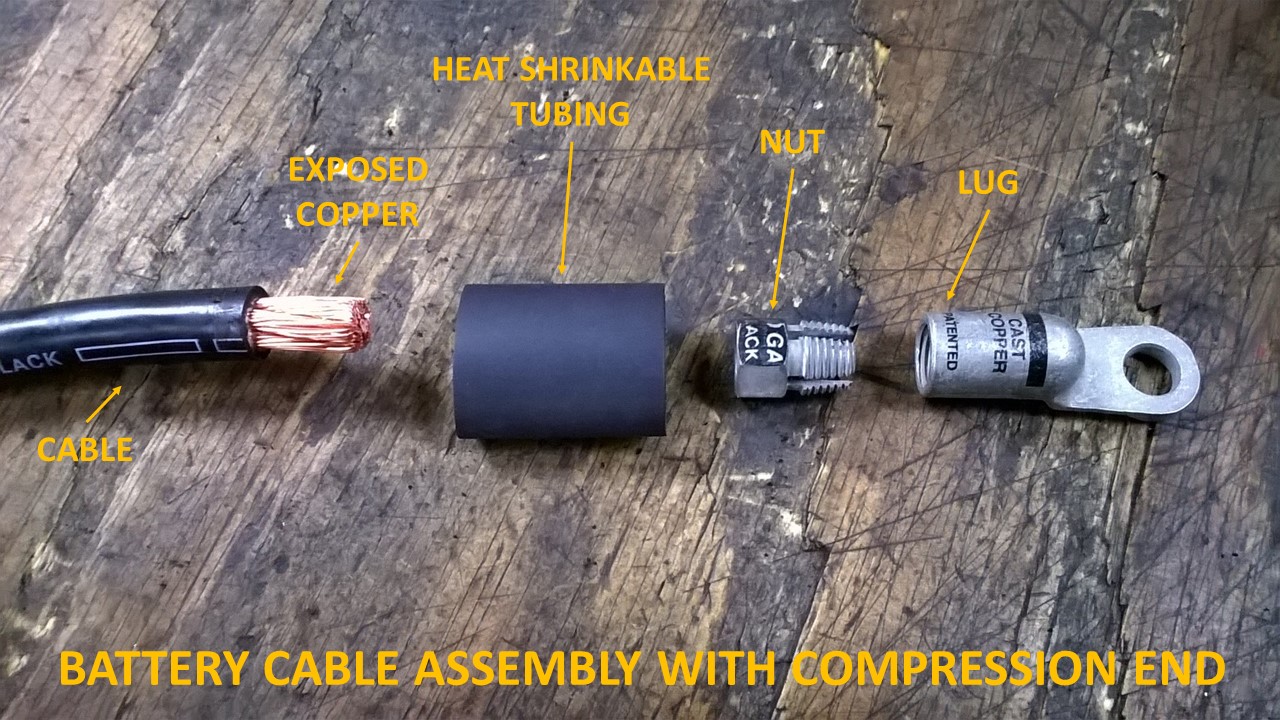

Connectors refer to the clamp or lug used to attach the battery cable to the battery terminal. A clamp is joined together by a bolt and a nut whereas a lug is a one-piece circular end that fits around the terminal of which it’s attached. All of our clamps, lugs, and fasteners are tin-plated with a cast copper alloy to resist corrosion.

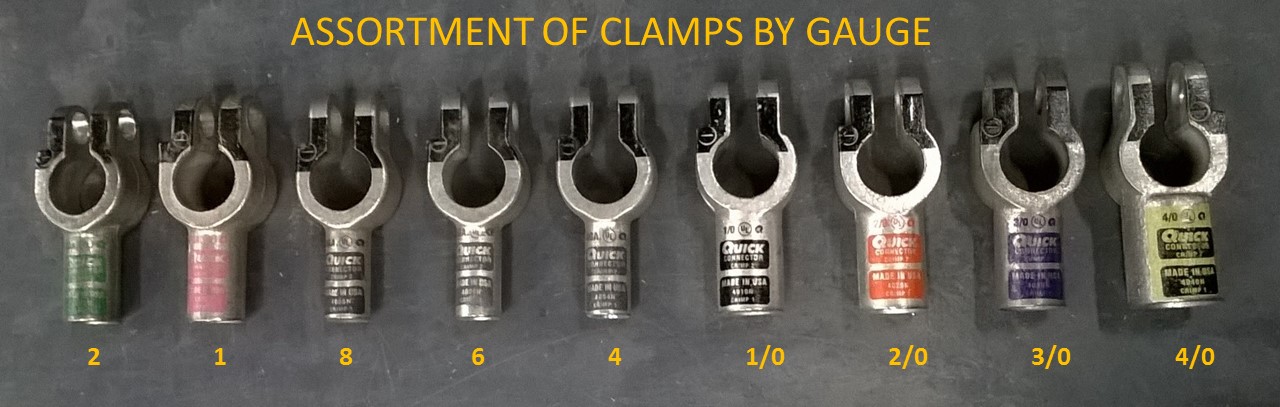

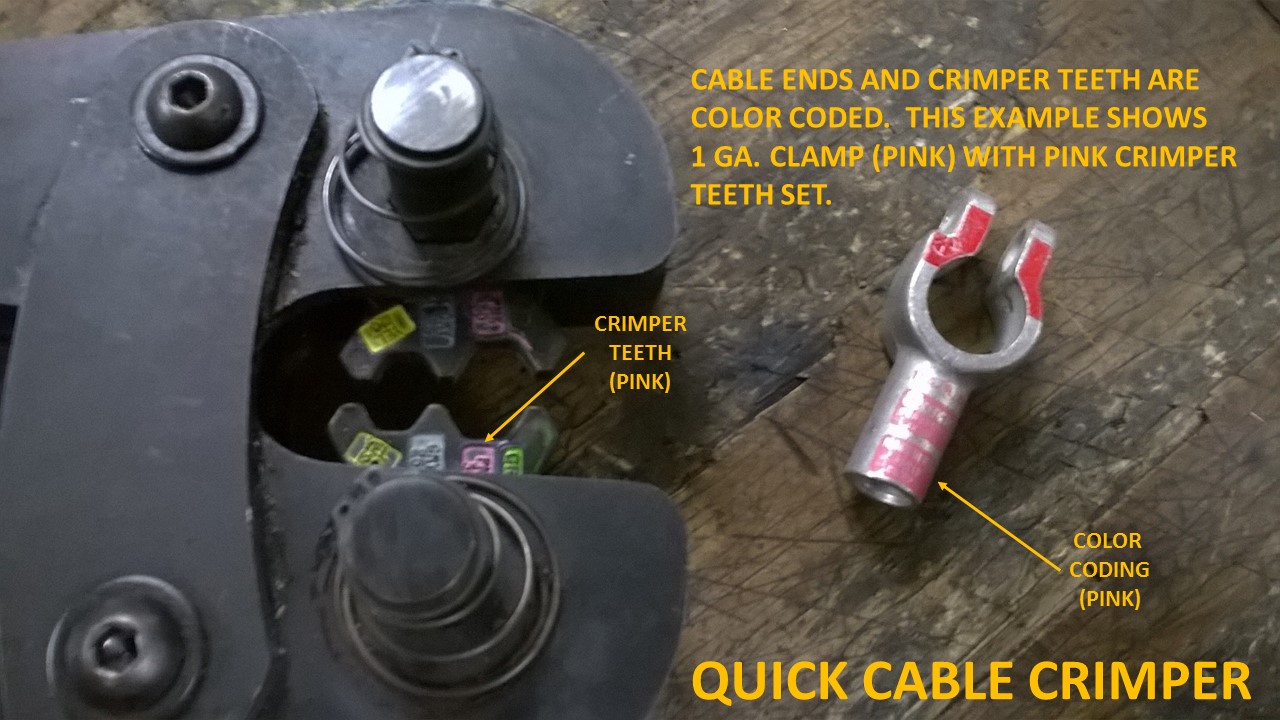

The connectors are color-coded (gray, green, pink, black, orange, purple and yellow) for easier cable gauge, or size, identification and also to denote positive or negative polarity. They are also imprinted with die codes that match the crimping tools necessary to complete an assembly.

These are the steps to attach the connector to the cable: First measure the length of the hollow end of the connector and mark that amount on the end of the cable. Using a utility knife or cutting tool remove the insulation and place the connector over the exposed wire. The connector should match firmly against the remaining insulation. Be sure the end is pushed all the way on before crimping.

Other features of QuickCable connectors:

- Thick wall

- Centered barrel and bolt hole

- Clamps the full height of a battery post for maximum electrical contact

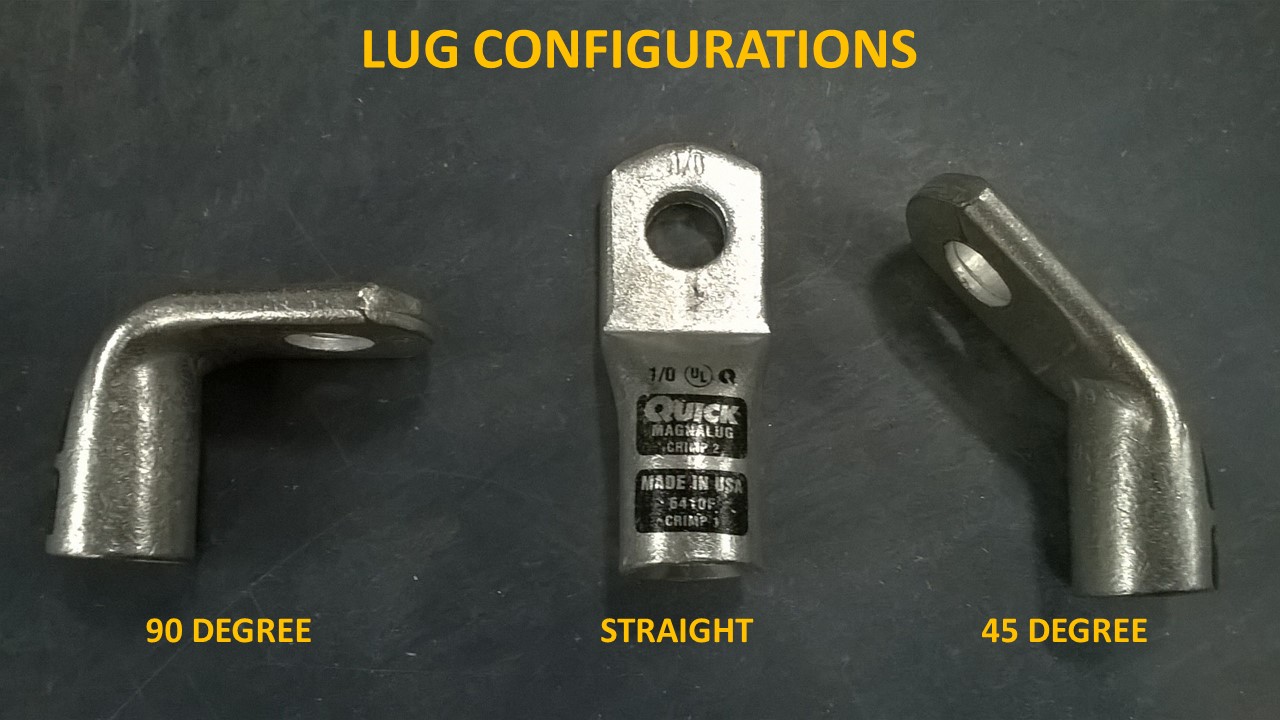

For tight spots, connectors are offered in a 45 and 90 degree angle as well as in a flag design.

Shop for Battery Lug Connectors

Copper tubing butt splices are obtainable to match the particular cable size in question.

Shop for Battery Butt Splice Connectors

A good connector to use for farming, construction, trucks and buses is the MagnaLug.

The benefits of a MagnaLug connector:

- Made of 100 percent copper

- Tin plated twice as thick as industry standards

- Longer, thicker, wider and stronger than standard lugs

- Exceeds SAE conductivity standards

Quick Compression Connectors with compression nuts are ideal for small and medium sized users such as tow trucks, maintenance vehicles, and field repairs. They can be installed with common hand tools, just strip 7/8” of insulation from the cable end then insert the bared-wire into the compression nut and thread that with the connector. Grip the compression nut with a wrench and turn until the nut seats.

Battery and Welding Cable

Battery cable is insulated with flame retardant PVC and is resistant to fuel, oil, acid, and salt. It is the OEM standard in the industry. Like connectors, battery cable is color-coded for identification. This way it’s easy to quickly identify gauge, connectors, and crimper needed. The generally accepted industry practice is to use black insulated cable for negative (ground) and red for positive posts.

When replacing cable, always install a heavier gauge cable, never lighter. In cold climates, a heavier gauge can also be used to improve starting. To find the gauge size, measure the bare conductor wire only, not the insulation.

Size 8, 6, 4: Garden Tractor

Size 6, 4: Compact Car, RV

Size 4: Standard Car

Size 1, 2: Full-size Car, Van

Size 1/0: Tractor, Light Truck, Construction

Size 2/0, 3/0: Heavy-Duty Tractor, Truck, Bus, Construction

Size 4/0: Extra Heavy Duty

As an alternative, welding cable is made with a very fine copper wire and insulated with synthetic rubber. It is more flexible than battery cable, especially in cold temperatures and it is easier to route in tight spaces.

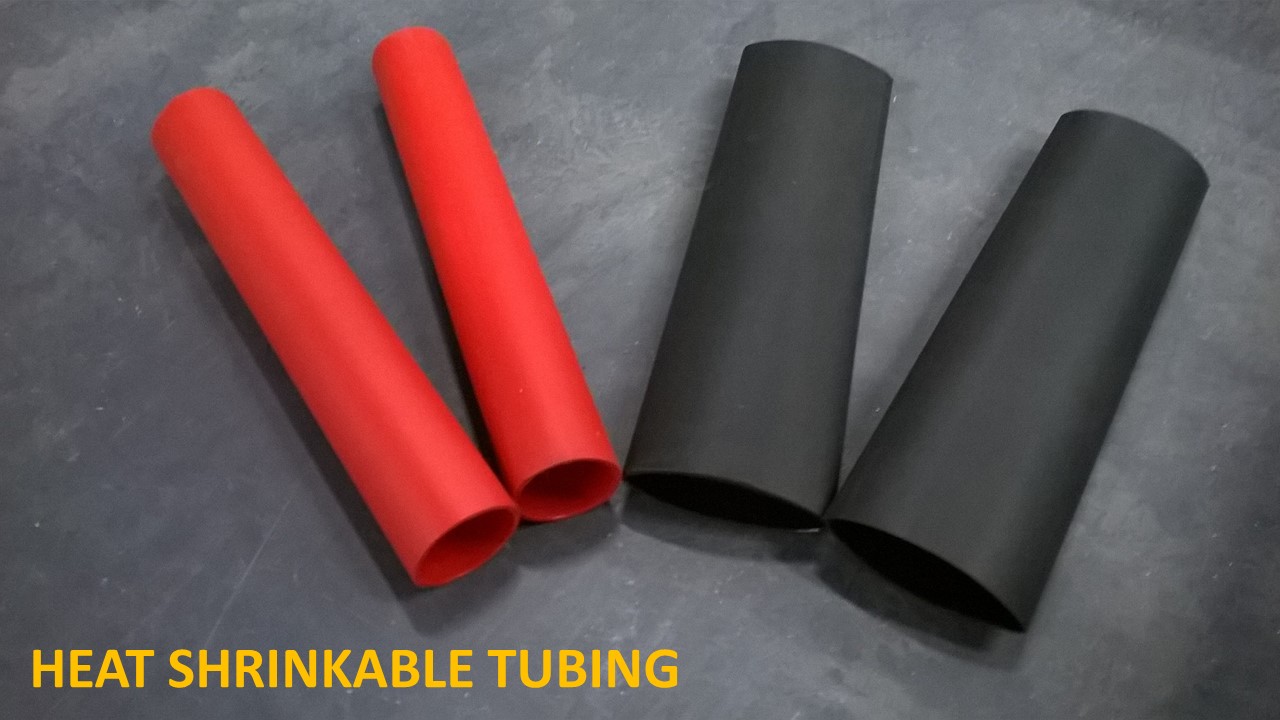

Heat Shrinkable Tubing

Shop for Heat Shrinkable Tubing

This tubing creates a corrosion resistant seal around the area where the connector covers the wire and meets the insulation on the battery cable. The inside surface is lined with a sealer which melts when heated and permanently seals the link.

The tubing is rated for -65 degrees F to +340 degrees F and is resistant to:

- Flame

- Acid

- Fuel

- Abrasion

Protectors

Battery Terminal Protectors reduce the possibility of shorts to the electrical system while lowering the chances of sparks and battery explosions. They cover the battery post/ cable connection area and are also color-coded black for negative and red for positive.

As for the cables themselves, they can be covered with an extremely flexible nylon loom for extra protection. It is slit on one side for easy install.

This shields the cables against:

- Heat (rated for 409 degrees F)

- Abrasion

- Electrical shorts

- Corrosion

Use a Quickcote Protective Compound to guard connectors and terminals.

Guards against corrosion from:

- Water

- Oils

- Damaging Gases

It has an easy brush-on application and can be used on all exposed electrical connectors. Doing this can prevent threaded fasteners from seizing. Protective washers can also prevent corrosion.

Crimpers and Cutters

The connectors are crimped to the cables using a hand-held or bench mounted lever-style crimping tool. A Brute Hammer style crimping tool for use with a hammer or vise is available as well. Copper cable cutters are also offered in bench mounted or hand-held models. Battery cable insulation strippers can save time and energy during production. Another accessory we provide is Booster Cable sets in case you need a jump-start.

Whether you need components to produce battery cables for your own operations, or you have a need for custom made assemblies at Royal Brass and Hose we have you covered. From connectors to protectors to wire we have the product available to get your vehicles started and keep your business thriving. Have additional questions about battery cables? Contact the RBH sales representative in your area or call 800-669-9650 to speak to a member of our customer service team. Our Ecommerce site can help guide your selection.

Our helpful Youtube video will show the crimping process. Watch the video.

Shop our battery cable and terminal products

All Battery Cables and Terminals